Zinc Alloy Die-casting Service

Custom Zinc Alloy Die-casting Service

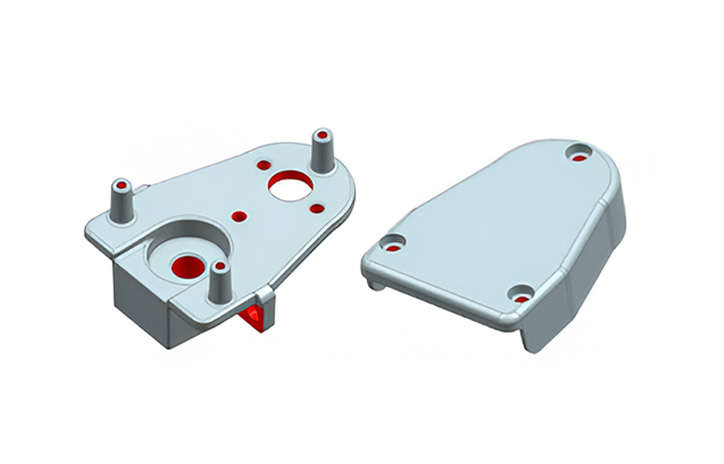

Zinc alloys are among the easiest materials to die cast, thanks to their high ductility and exceptional impact strength. These properties make them ideal for mass-producing small, intricate parts with excellent dimensional accuracy. The process is not only highly productive but also cost-effective, offering a reliable and economical solution for high-volume manufacturing needs.

What is Zinc Alloy Die-casting?

Zinc alloy die casting is a rapid, hot chamber process known for its efficiency. It utilizes a gooseneck mechanism submerged in a furnace of molten metal. The molten metal flows automatically into the shot chamber through an opening in the gooseneck. A vertical plunger then seals the opening and forces the metal into the die cavity under high pressure. The part solidifies almost instantly and is ejected from the mold, making this process ideal for high-speed, high-volume production of precision components.

Advantages of Zinc Die-casting

- Zinc alloy features a narrow crystallization temperature range, low melting point, and excellent fluidity, making it easy to fill and form. It resists mold sticking, enhancing die-casting mold longevity.

- With high mechanical strength, zinc alloy can be die-cast into complex, thin-walled components. It supports various surface treatments, particularly electroplating, and maintains strong performance at room temperature.

- It is electrically and thermally conductive, highly corrosion-resistant, and fully recyclable.

- Zinc alloy ensures high precision and exceptional performance in applications.

Applications for Zinc

- Complex net-shaped zinc housings with precise thin walls provide superior electrical performance and effective shielding properties.

- As the leading supplier of zinc components for a wide range of consumer electronic devices, we leverage our advanced multi-slide die-casting technology and unmatched thin-wall manufacturing expertise.

- Zinc's outstanding castability, wear resistance, and structural integrity make it the perfect material for creating intricate, multi-faceted shapes essential for applications in automotive safety systems and the electronics industry.